Products Center & Service

PROTOTYPING

We can prototype new designs at incredible speed thanks to our highly skilled design engineers, harnessing our global expertise and delivering via our local teams.

We can prototype new designs at incredible speed thanks to our highly skilled design engineers, harnessing our global expertise and delivering via our local teams.

|

Product details |

|

|

Part name: |

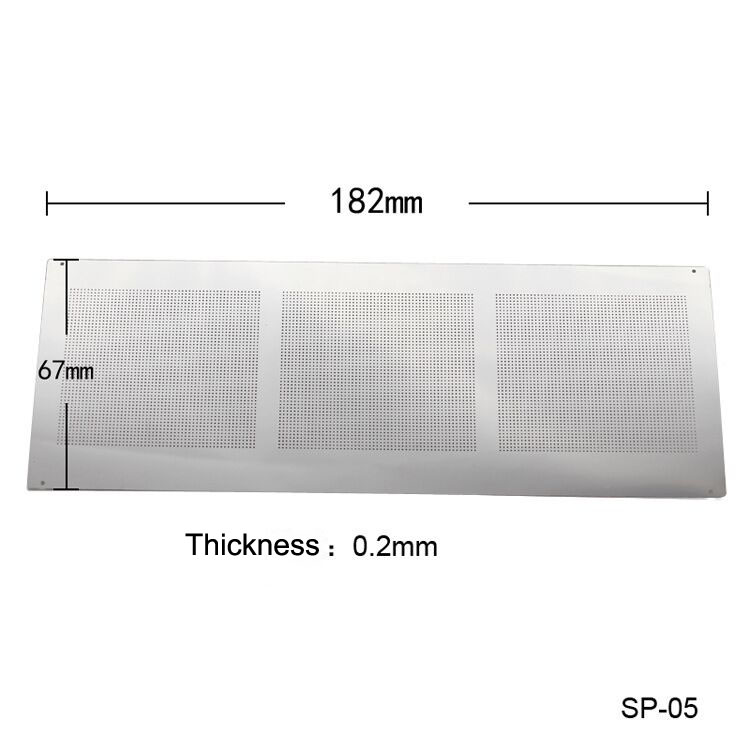

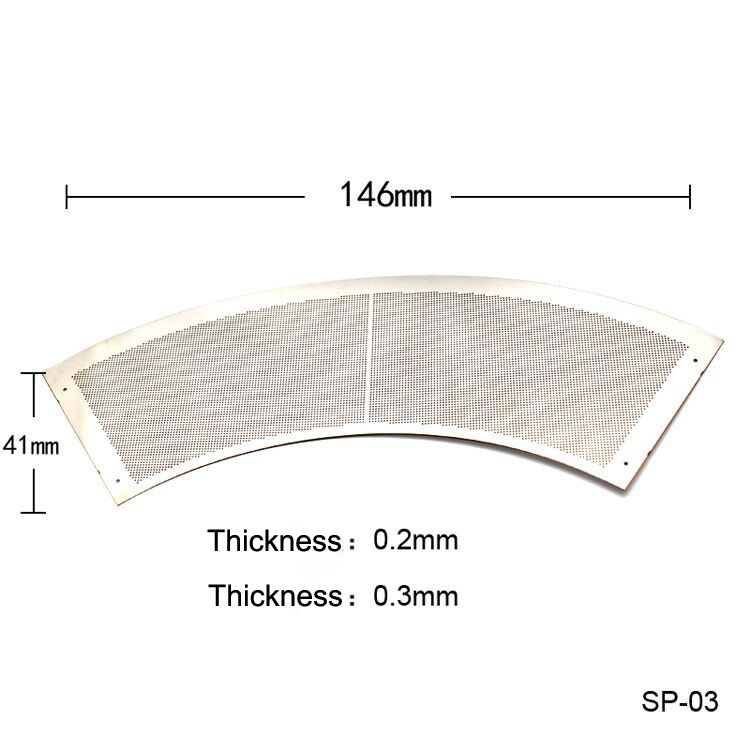

Vacuum cleaner filter made of stainless steel |

|

Material: |

Stainless steel 304/301/316/430, brass, brass alloy or copper |

|

material thickness(mm): |

T=0.1mm/0.12mm/0.15mm/0.2mm/0.25mm/0.3mm, |

|

Application: |

Vacuum cleaner filter made of stainless steel |

|

Filter specification: |

no blind holes, burr free |

|

Price: |

Base on the material kind, thickness, accurancy, quantity. For the formal quotation, please send us the drawing. |

|

Prodcution capability: |

1. Machines: 1 reel to reel exposure machine, 6 photo etching machines.2.Can photo etching filter for liquids or gases more than 1000 square meters per day, about 100 thousand pcs (size 280*220 mm) per month,We are the leading supplier of photo etching factory in domestic China. |

|

Samples: |

1. More than 300 items new samples will be finished here in our factory each month. These years, raw material and labor cost raise a lot, so we had to charge for sample cost, we call it tooling cost or start fee or sample cost.2.Lead time: Generally 1-3 working days. |

|

Lead time for mass production: |

Generally, the lead time for mass production of Vacuum cleaner filter made of stainless steel is 5-7 working days, this depend on the exactly quantity |

|

QC report: |

Samples and mass products can be checked by 2D measuring instrument, |

|

Why use photo etching to make Vacuum cleaner filter made of stainless steel |

|

|

1. Easy for adjustments that embossing also possible fo half the thickness leave |

|

|

2. Can half etching company´s logo |

|

|

3. Photo etching filter for liquids or gased can have high accurancy to +/-0.01mm,what´s more, the quality is high too |

|

|

4. Be suitable for thin and microscopic fabrication on metals, will not change the material specific after etching |

|

|

5.Two types of image files ( DXF/DWG) enabled |

|

|

6.Our special team makes possible quick delivery for prototypes |

|

|

Benefits of photo etching compared with stamping |

|

|

No need for expensive DIE´s |

|

|

Can be fabricated more thinner metals(t=0.025-1.2 mm) |

|

|

Pore complex and groove can also easily adjust the depth or groove |

|

Tel.:+86-755-89375091 Fax.:+86-755-89375092 E-mail: sales@sg-etch.com

Address: 301, Building A, North Plant, No. 103,Pingxin North Road, Mugu Community,Pinghu Street, Longgang District, Shenzhen,China 518111

copyright@2007-2015@SinoGuide Technology Ltd.