News Center & Categories

DESIGN GUIDE

All dimensions, tolerances and configurations are functions of the thickness of the material being photo etched and should be considered during the design process.

All dimensions, tolerances and configurations are functions of the thickness of the material being photo etched and should be considered during the design process.

Summary: Typical Etched Metal Parts SinoGuide Technology has developed a new and highly efficient etching chemistry that can improve the quality and dimensional tolerance accuracy of aluminium component manufacture to a new high.

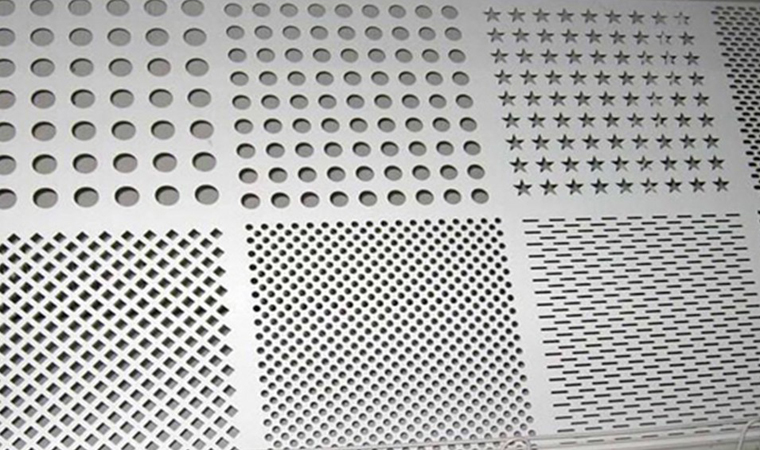

Over the past several decades, the photochemical etching process has proven to be a versatile and cost effective method of fabricating thin-gauge metal parts in many alloys. SinoGuide Technology has developed a new and highly efficient etching chemistry that can improve the quality and dimensional tolerance accuracy of aluminium component manufacture to a new high.

Aluminium and its alloys are increasingly prized in engineering for their lightweight durability that enables energy saving. However, they are generally considered to be difficult, slow and inefficient to etch using conventional chemistry. Consequently many users resort to punching, stamping or laser cutting to produce profiles but this comes at cost... stressing and heat distortion of the metal and the production of burr edges that have to be removed in a seperate process.

With the introduction of its ACmE process (Aluminium Compliant molecular Etching) SinoGuide has a proven production route that is not only far quicker but also safer, and more controllable. It produces higher quality components with burr-free crisp edges and higher definition features that could not have been contemplated using the old technology.

This new and exciting ACmE technology has been developed as part of a KTP (Knowledge Transfer Partnership) in association with a local University. SinoGuide personnel have worked closely with University experts and the company based KTP Associate post-graduate to design the chemical reaction at a molecular level and subsequently develop the process to optimise its efficiency.

Fast - Efficient - Flexible - Compliant Process, High Aspect Ratios, New Levels of Quality Achievable, New Tighter Tolerance Standards. Economical.

SinoGuide is the industry expert for photo chemical etching in high production volumes. Our unique chemical etching process delivers highly accurate metal parts with tightest tolerances. With highest reproducibility superfine structures are continuously etched into thin metal band - starting from 25 micron thickness.

Our photo-chemically etched parts are always clean, burr- and stressfree. These customer specific products from stainless steel and a wide range of other metals are used in various precision applications and industries worldwide. Micrometal - excellence in etching.

Due to its properties, including high temperature resistance, high strength to weight ratio and corrosion resistance, aluminum is used in a wide variety of applications. It is used to manufacture covers and shields, lids and shims, often for high wear components. Etched aluminum parts can be tin plated, which allows them to become solderable. They are widely used in the aerospace and defense industries due to their light weight and high strength properties.

Want to know more about our Aluminium Etching capabilities? Please contact us today on sales@sg-etch.com.

What's Difference Between Photochemical Etching and Stamping

Talk to Us

Our engineers are on hand to discuss your etching component requirements and advise on design parameters.

Tel.:+86-755-89375091 Fax.:+86-755-89375092 E-mail: sales@sg-etch.com

Address: Rm#911-912,Block 12, Huayao BLG, No.1 Pingan Road, Pinghu Town,

Longgang district, Shenzhen, P.R.China 518111

copyright@2007-2015@SinoGuide Technology Ltd.