Writer: admin;

Source:SinoGuide Team;

Date:2018-11-12

Summary: The answer depends on what application it is intended for and how many pieces. Basically, there are several factors to consider: cost, time, volume, precision, and flexibility.

Flexibility

Flexibility

Photo etching tooling is created on a photoplotter using mylar film, unlike costly conventional methods such as stamping. Moreover, tooling is generated within hours. This low-cost method allows the tooling engineer to experiment with various designs making it easy to modify and significantly reduce project time. The tooling's flexibility allows for future part revisions if necessary, which makes it ideal for prototypes or short runs. Photochemical etching can be more cost-effective when it comes to tooling. A stamping die could take weeks to make and cost thousands of dollars. Conversely, photochemical etching tooling is made of film from a transposed CAD design and takes a couple of hours to produce and only costs up to $300.

Metal Properties Remain Unaltered

Whereas other machining methods can alter metal properties with heat or mechanical stress during production, the internal structure of the metal remains unchanged when using the photochemical etching process. The hardness, grain structure, and ductility of the metal are unaffected This advantage is significant for the functionality of many product applications.

Metal Etching FAQs

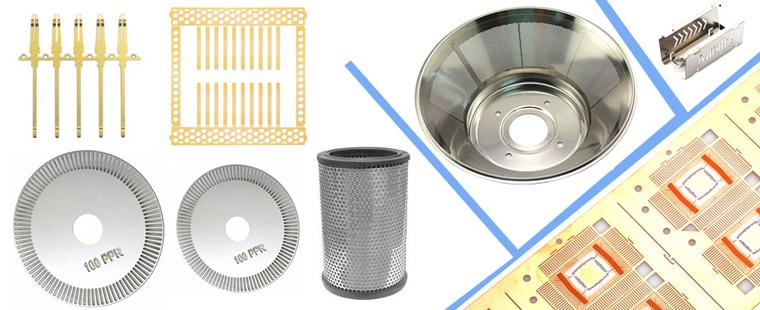

tight tolerance etched parts

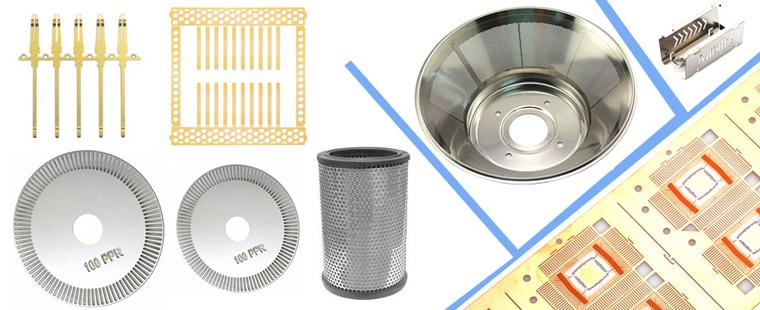

Low-cost repeatability

The tooling is designed to yield as many pieces as the part design will allow. Because of this repeatability, large production runs are an inexpensive option compared to stamping and laser. Additionally, we can etch company logos, part numbers or other identifying marks at no extra cost. The tooling remains the same whether it's for one part or a million.

Burr-Free Tight Tolerances

Another chemical etching advantage is the production of thin burr-free metal parts. Other processes often leave burrs that can interfere with the proper performance of the part. The metal etching process eliminates the need for costly and time-consuming deburring procedures. Because a phototool is a replica of a part's dimension and does not wear like hard tooling, it is easy to maintain tighter tolerances.

Photo-chemical etching process: Employee Inspection

Production pieces photo etched parts large quantity

Quick Turnaround

The elimination of mechanical tooling and its long lead time, plus the absence of surface burrs and deburring requirements, speed the process from tooling design to the actual part.

As you can see, it really depends on what method can best meet your project needs. If you are interested in learning more about photochemical machining benefits, click contact us now.