News Center & Categories

DESIGN GUIDE

All dimensions, tolerances and configurations are functions of the thickness of the material being photo etched and should be considered during the design process.

All dimensions, tolerances and configurations are functions of the thickness of the material being photo etched and should be considered during the design process.

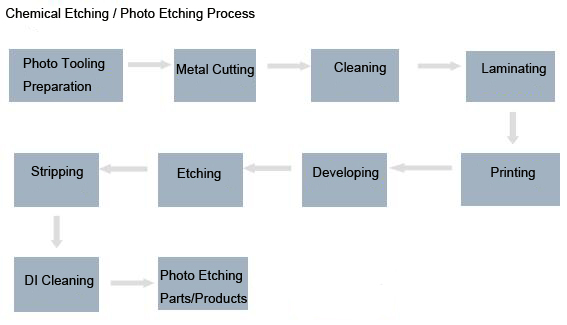

Summary: Chemical Etching / Photo Etching step-by-step: 1. Photo tooling preparation Data is received electronically from the customer in a variety of formats such as DXF / DWG; or via a fully dimensioned drawing; etching compensations are then adde

We all know just how versatile the photo etching process can be, allowing us the opportunity to work on a variety of different materials and metals with highly accurate results and low levels of error. The use of chemicals to etch out a design or pattern in metals that are otherwise strong and durable is one that is cost effective, fast and highly beneficial across a number of industries.

Photo chemical machining is the fabrication of sheet metal components using acid to chemically remove the unwanted material from the sheet leaving you with exceptional parts.

Data is received electronically from the customer in a variety of formats such as DXF / DWG; or via a fully dimensioned drawing; etching compensations are then added. A front and back registered film (Photo tool) is plotted from the data. It is important that the data / drawing received represents the finished component required.

Suitable metal is sorted by allocated stock, type, thickness, grade and cut to applicable sheet size.

The metal to be used is chemically cleaned to remove any rolling oils or contaminants from the surface, this is important as contamination will inhibit the application of the photo resist and could negatively impact the quality of the finished etched part.

The design is printed negatively on a film sheet. The metal sheet is then sized ,cleaned and placed between two sheets of UV sensitive film, known as laminating. Dry film photo resist is applied to the metal sheet through heated rollers to bond the photo resist to both sides of the sheet.

The Dry Film laminated sheet has the photo tool image applied to it by exposing the image onto the metal using a UV (Ultra Violet) light source. The component image is transferred to the metal sheet.

Chemically develop the metal sheet washing away the areas where the etchant is going to attack.

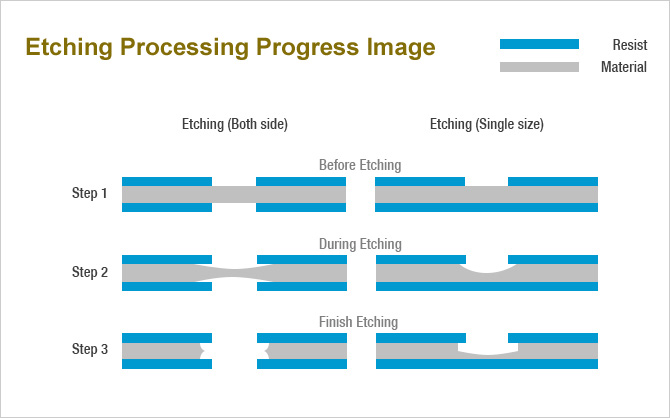

Etching is the actual immersion of the metal sheet into the etching machines and the action of the etchant on the unprotected metal areas to be milled. The etching rates of the metal sheet are based on a number of factors including the concentration and composition of the etchant, the material to be etched, and temperature conditions. Etch rate is normally determined by using a small sample of the same material to be etched. Critical dimensions taken from the customer drawings are dimensionally checked at this stage and first off evaluation is carried out prior to the batch etching.

Rinse and strip the photographically resistant dry film from the metal sheet, the etched sheet is now ready for final inspection.

Components can now have secondary operations applied such as forming, plating, heat treatment, etc..

What's Difference Between Photochemical Etching and Stamping

Talk to Us

Our engineers are on hand to discuss your etching component requirements and advise on design parameters.

Tel.:+86-755-89375091 Fax.:+86-755-89375092 E-mail: sales@sg-etch.com

Address: Rm#911-912,Block 12, Huayao BLG, No.1 Pingan Road, Pinghu Town,

Longgang district, Shenzhen, P.R.China 518111

copyright@2007-2015@SinoGuide Technology Ltd.