News Center & Categories

DESIGN GUIDE

All dimensions, tolerances and configurations are functions of the thickness of the material being photo etched and should be considered during the design process.

All dimensions, tolerances and configurations are functions of the thickness of the material being photo etched and should be considered during the design process.

Summary: Different metal cutting processes produce different effects at the cut line. Stamping and punching can leave a deformation and a burr on the die side of the plate. Laser, plasma and EDM can leave a heat-affected zone or recast layer.

Different metal cutting processes produce different effects at the cut line. Stamping and punching can leave a deformation and a burr on the die side of the plate. Laser, plasma and EDM can leave a heat-affected zone or recast layer. Abrasive slurry water jet can leave a somewhat erose sidewall. And photo chemical machining has its own sidewall artifact that we call a "feather."

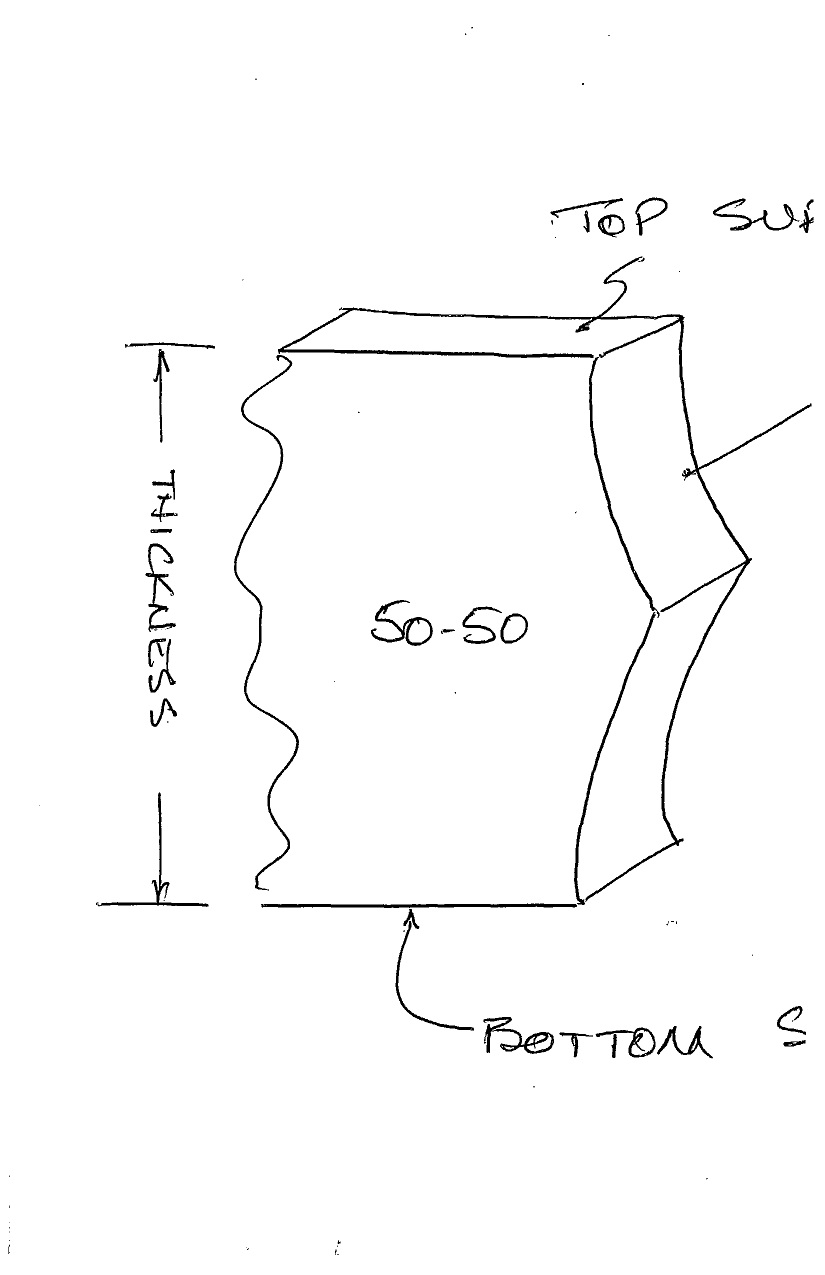

Most often, photo etching is done from both sides equally and at the same time as a "50/50" etching ratio. As the etchant penetrates from each side of the metal, the cutting path widens at the surface as it deepens. This effect occurs at the predictable rate of .00025" in width per .001" of cut depth. The feather reaches its maximum at the point of breakthrough. To calculate the feather, multiply .00025" by half the metal thickness.

Unless otherwise specified, we measure to the feather. If your application is more sensitive to total surface area, we need to know that so we can discuss with you the implications with regard to mechanical dimensions at the feather.

There are times in photo etching that we use other etch ratios, such as 60/40 or 80/20. Usually, the applications for this involve filtration to produce a hole on one side that is smaller than the metal thickness would typically allow. The rule of thumb is that the minimum hole size is 115% of the metal thickness.

With a ratio etch, we treat each side of the metal as if it were a different thickness. If we wanted to use an 80/20 ratio on .010 material, we would treat the 20% side as if it were .004" thick and the 80% side as if it were .016 thick. With this ratio, we could put a .005" hole on the 20% side and the 80% side would be about .018. The center distances on the holes would have to be the 80% side plus the overall metal thickness.

Using a ratio etch, the feather will move to the new breakthrough line, in our example it would be .002" from the 20% side of the sheet and the feather will be driven by the 80% side and will therefore be .00025" x 8, or .002".

More than world’s leading chemical etching supplier, SinoGuide is generally considered to be the technology leader, having developed new innovative process routes that have reset benchmarks for capability, precision, accuracy and repeatability.

Our customers benefit from:

- Total quality management system.

- Every process will be checked by QC system.

- Professional packing teams and standard packing for ocean or air transportation.

- Capacity and technical resource unmatched in the industry.

- Professional and passion sales team.

- Customized designs is available with CAD/PS drawings.

What's Difference Between Photochemical Etching and Stamping

Talk to Us

Our engineers are on hand to discuss your etching component requirements and advise on design parameters.

Tel.:+86-755-89375091 Fax.:+86-755-89375092 E-mail: sales@sg-etch.com

Address: Rm#911-912,Block 12, Huayao BLG, No.1 Pingan Road, Pinghu Town,

Longgang district, Shenzhen, P.R.China 518111

copyright@2007-2015@SinoGuide Technology Ltd.