Products Center & Service

PROTOTYPING

We can prototype new designs at incredible speed thanks to our highly skilled design engineers, harnessing our global expertise and delivering via our local teams.

We can prototype new designs at incredible speed thanks to our highly skilled design engineers, harnessing our global expertise and delivering via our local teams.

Applications

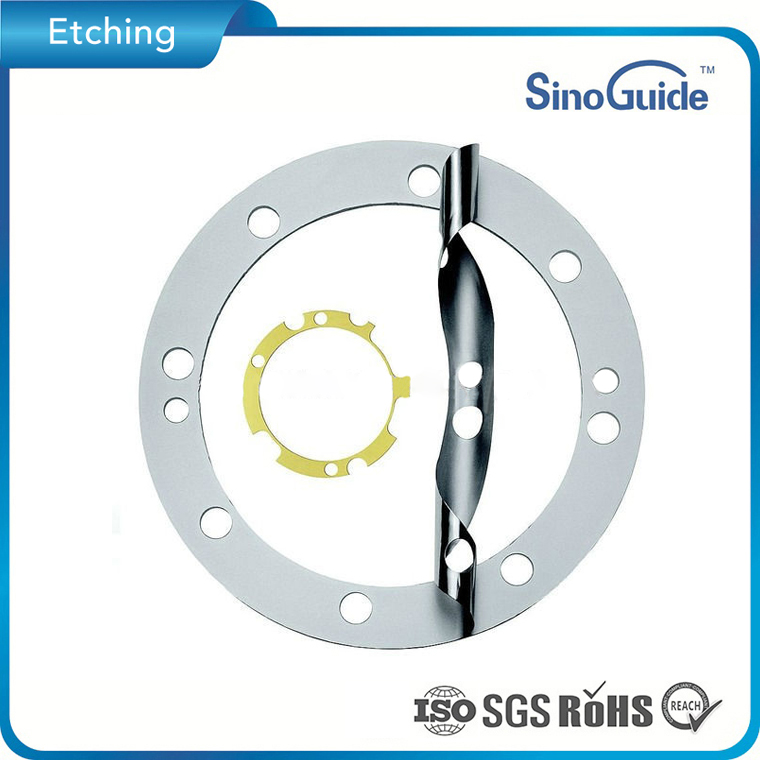

Valve, Spring Shims - Copper, Brass, Stainless Steel, Aluminum Shims

The laminated shims are mainly used to adjust the gap or center line between two equipements, they are much more convenient to use comparing to single layer shims.

Laminated shims are generated by a few thin shims layer by layer, you can peel off some layer until you get the required thickness shim you want, it is flexible to use for the adjustment.

Specification

|

Product Name |

Laminated Shims |

|

Material |

Stainless Steel / Aluminum / Alloy |

|

Material Thickness |

Customized |

|

Minimum Hole Dimension |

Customized |

|

Minimum Tolerance |

Customized |

|

Process After Etching |

None |

|

Prototype L/T |

3~5 Working Days |

|

Production L/T |

5~8 Working Days |

Advantages of Photo Etching

• Low tooling cost, no need for expensive DIE/Mold

• Can fabricate more thinner metals (T=0.02-1.2 mm)

• No alteration process, the characteristics can be obtained as the designer intended

• High accuracy

• Various apertures, shapes and bar combinations

• Burr & Stress free manufacturing method

• Prototypes – fast turnaround to meet your needs

• High volume capabilities

Value Added Services

• Plating / PVD coating

• Painting / Printing

• Laser marking

• Polishing / Electro-polishing

• Anodizing

• Stamping / Punching

• Other specific requirements

Product Photos

Photo Etching Procedure

Company Information

Why Choose SinoGuide

Experts From R&D to Production

Experts From R&D to Production

Main Equipment and Capacity

Main Equipment and Capacity

Due to our high performance and reliable equipment, SinoGuide can provide high quality and performance photo

etching components for customers.

Furthermore, our high production capacity can also fulfill your high-volume orders and shorten the lead time

• Pre-treatment machine --- 2 Sets

• Coating machine --- 5 Sets

• Exposure machine --- 3 Sets

• Developing machine --- 2 Sets

• Etching machine --- 6 Sets

• 3D measuring instrument machine --- 2 Sets

• 2.5D measuring instrument machine --- 2 Sets

• Microscope --- 10 Sets

• Salt spray testing machine --- 1 Set …etc.

• Sewage treatment system

• Daily Capacity: 200K Sheets

Strong Logistics System

Strong Logistics System

metal shims, stainless steel shim, brass shim stock, metal shim stock, aluminum shim stock, valve shims, brass shims, copper shims, valve spring shims

SinoGuide etches custom shims, gasket and washers, flat, formed or assembled, for a variety of technical applications, including energised springs for Formula 1, damping shims for fuel injection and ultra-thin, titanium shims for satellite fuel tanks. From simple spacer washers to complex cylinder head gaskets for racing engines, photo etched springs, gasket and washers are accurate to ±0.025mm, flat-and burr-free, with no rough edges that could interfere with other mating components.

Tel.:+86-755-89375091 Fax.:+86-755-89375092 E-mail: sales@sg-etch.com

Address: Rm#911-912,Block 12, Huayao BLG, No.1 Pingan Road, Pinghu Town,

Longgang district, Shenzhen, P.R.China 518111

copyright@2007-2015@SinoGuide Technology Ltd.