Writer: admin;

Source:SinoGuide Team;

Date:2018-04-16

Summary: SG ETCH has the expertise to chemically etch stainless steel, with excellent results. Our state-of-the-art chemical etching process is cost-effective and repeatable, producing even the most intricate parts reliably and to the tightest tol...

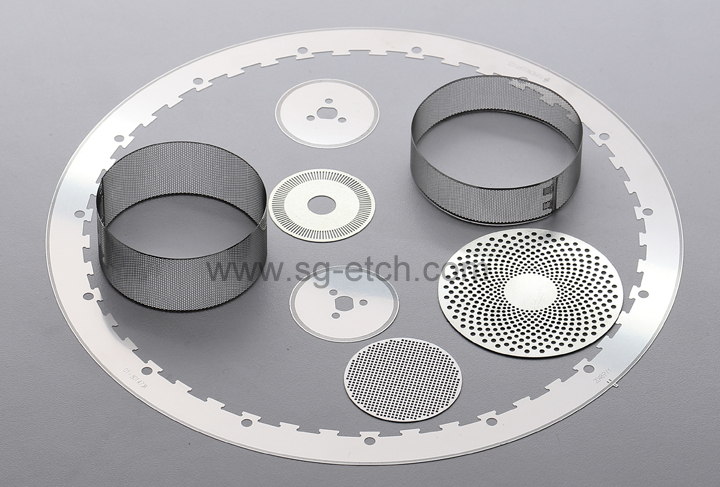

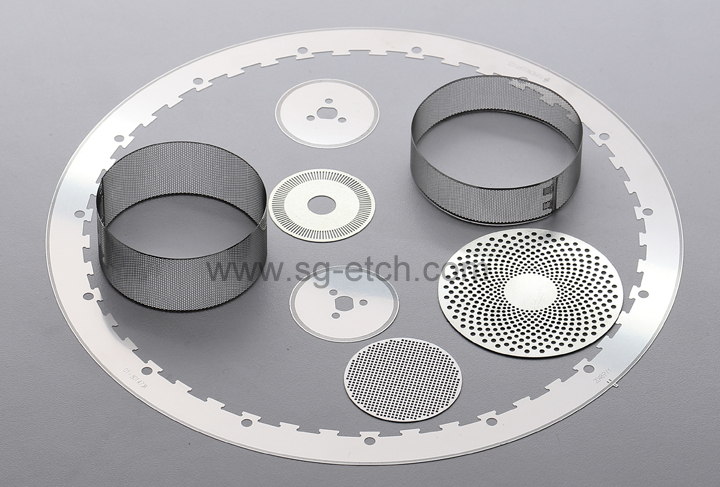

SG ETCH has the expertise to chemically etch stainless steel, with excellent results. Our state-of-the-art chemical etching process is cost-effective and repeatable, producing even the most intricate parts reliably and to the tightest tolerances. Etched parts are machined without affecting the remaining material or surface finish and have a clean cut with no heat-affected zones or burrs. SG ETCH’s process can be used to create exacting half-etch and partial-etch areas that are impossible to produce with other manufacturing methods. Partial and half-etch processing can be used to create features with varying thicknesses, mark the surface of a component with a logo or part number and facilitate bending during fabrication and assembly. Chemical machining is also used to micro-etch the surface of completed components to improve bonding in later processes.

Photo Chemical Etching of stainless steel components is the ideal process for the small and intricate parts that are often found in medical, aerospace, and other highly technical industries. The technology used in chemical etching metal is cost effective and quick with a high level of precision.

From the simplest geometries to the most complex, metal etching is a very cost effective solution for precision metal parts.

Stainless Steel Photo Chemical Machining Capabilities

The advantage of our stainless steel etching process is that it is a cost-effective and repeatable way to produce even the most intricate parts. There are many manufacturing benefits because our process can chemically machine parts without affecting the remaining material and surface finish. Etched parts are cut clean with no heat-affected zones or burrs. Our process can also be used to create half-etch or partial etch areas that are impossible to produce with other manufacturing methods. This can be used to create features with varying thicknesses, or mark the surface of a component with a logo or part number. Chemical machining is even used to micro-etch the surface of completed components to improve bonding in later processes.

Applications for Stainless Steel Photo Etching

Stainless steel is a versatile metal that is used for a variety of products in every industry. SinoGuide Tech etches stainless steel springs for aerospace components, flat-wires for medical catheters, covers for telecommunication circuit boards and surgical cutting tools. Our control of edge features can even ensure a very sharp edge for use on medical cutting blades.

Stainless steel photochemical machining is exceptionally well suited to producing mechanical components such as shims, spacers, gaskets, pointers, dials, clips, diaphragms, springs, pressure membranes, flexures and many other applications.

Metal parts with complex geometries (odd shapes, lots of holes, etc) are often far more cost effective to produce by photo etching than by stamping, punching; laser, plasma or waterjet cutting; or wire EDM.