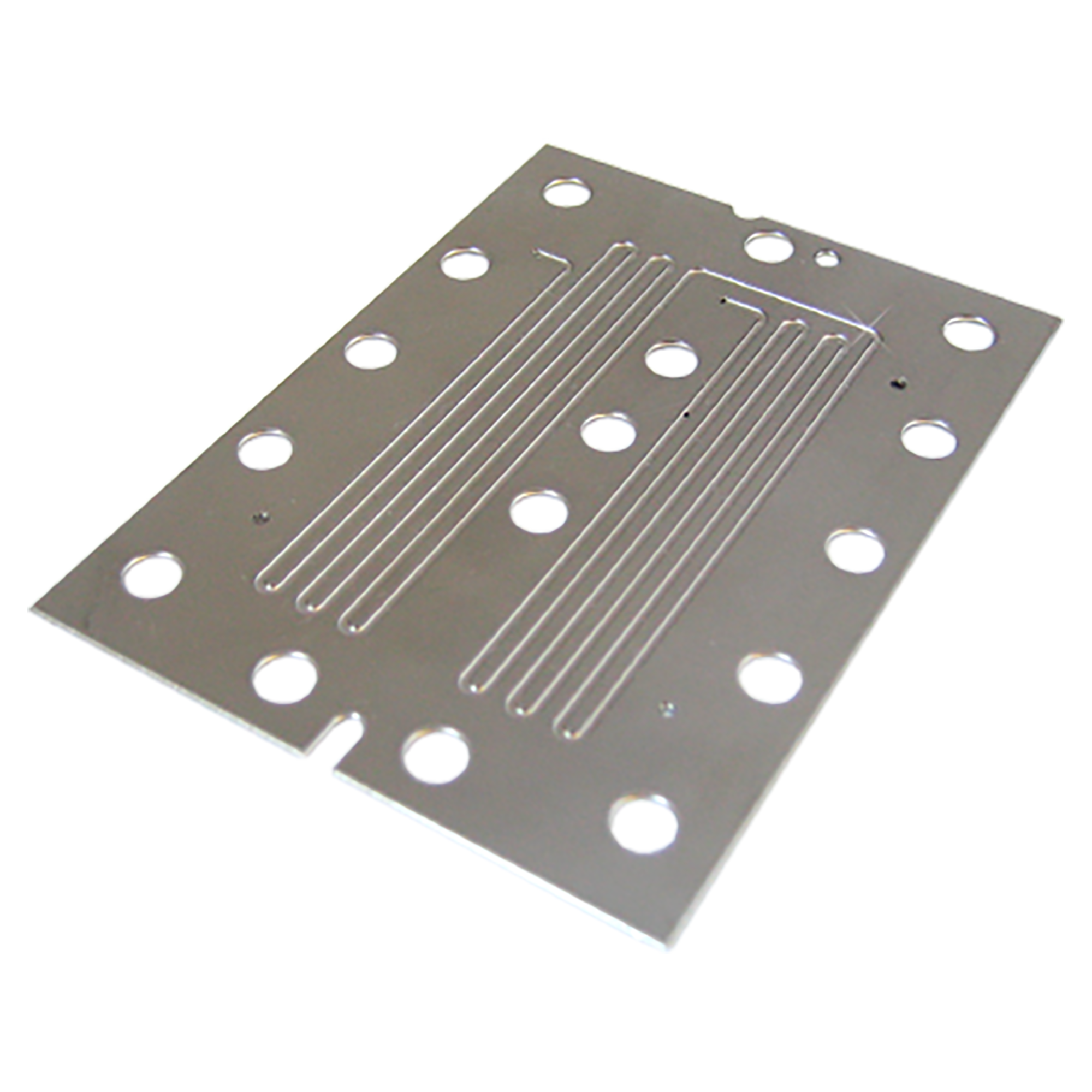

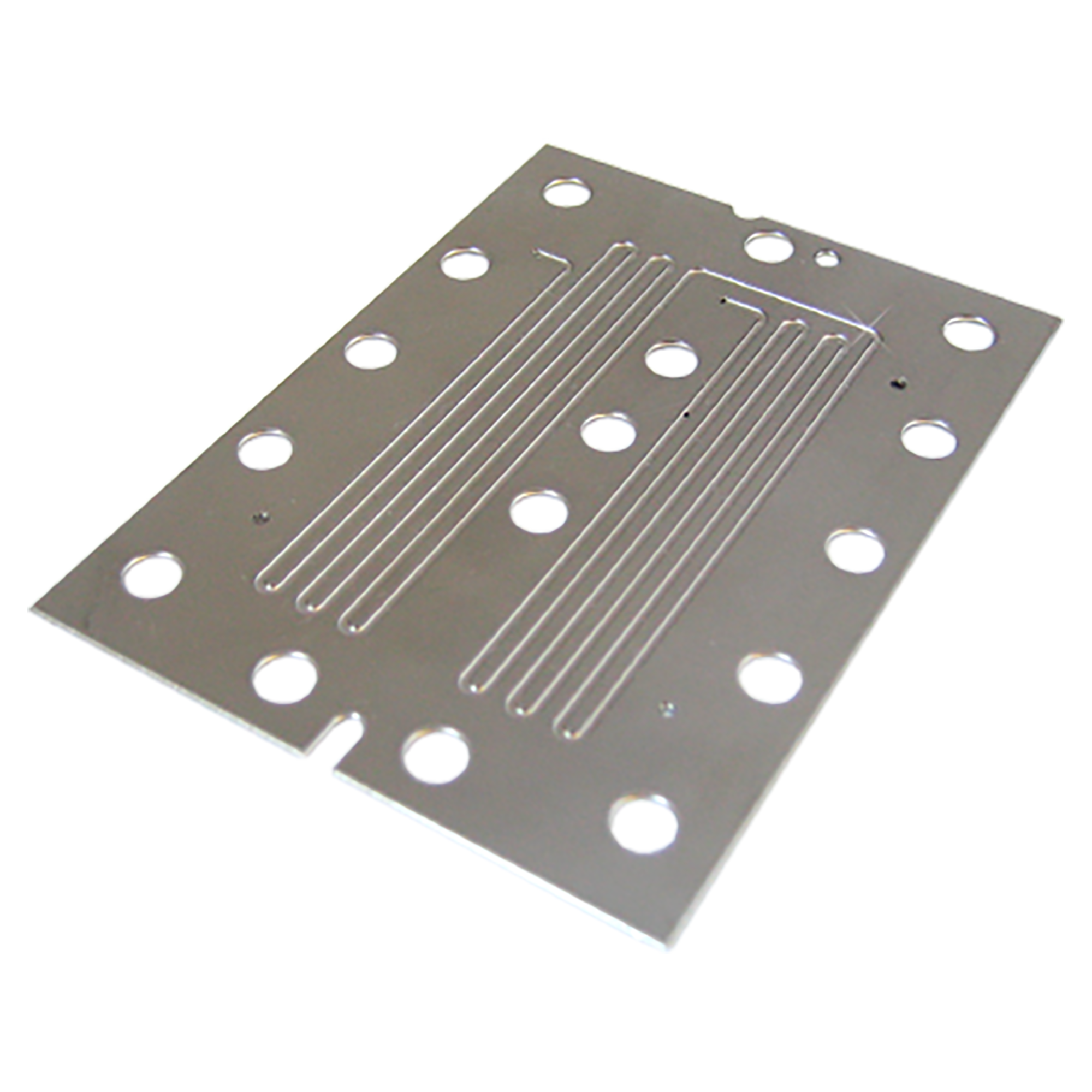

If you need photo chemical milling for a precision part we are one of the most capable and affordable sources and we can get the job done right. Photo chemical milling is a process that produces 2D part shapes by creating a chemical resist mask on the surface of sheet metal and chemically dissolving material from unmasked areas. We stock a wide variety of materials, use state-of-the-art machines and diligently follow all design specifications. We continually strive to improve and optimize our processes and maximize customer convenience. Our customers range from inventors to businesses to government agencies. We are focused on quality and customer service.

The chemical milling process utilizes chemicals rather than cutting tools to etch shapes in metal. Depending on the design of the part and desired volume of parts necessary, chemical milling can be an economical machining option, and it is regularly employed for a wide number of applications. Tooling for chemical milling is relatively simple, as it is generated using CAD software, with little to no need for replacement parts. Additionally, the process does not alter the structure of the remaining metal, which occurs in a variety of other physical machining processes. However, the process is only suitable for metals of relatively limited thicknesses, except in situations where only etching is required.

CHEMICAL MILLING (CM), also termed chem milling, chemical machining, chemical contouring, and chemietching, is a method of processing structural metal parts by controlled chemical etching. The process either thins the parts in specific areas or removes metal from all surfaces. Areas from which metal is not to be removed are protected by special coatings termed maskants or masks, and parts are etched by immersion in a tank of etchant.

What types of products are typically fabricated by photo-chemical machining?

Virtually any product type has photo-chemical machining applications. Common industries served include aerospace, electronics, automotive, medical, computer, instrument and decorative. Typical parts produced are heat sinks, shields, covers, lids, gaskets, springs, encoders, disks, lead frames, grids, screens connectors, panels, shims, bus bars, combs and decorative findings.

Most of the process applications are for producing parts with high strength-to-weight ratios. Chemical milling differs from chemical blanking, which involves the etching of very thin metal parts in spray chambers.

We are one of the leading manufacturers and suppliers of a wide range of Chemically Etched Metal Components. These are widely used in various applications in different sectors of electrical & electronics, aerospace, mechanical & automobiles, name plates and stencils. These components are manufactured using high quality materials along with the latest methodology in sync with the International standards. We offer these Chemically Etched Metal Components in various specifications at very reasonable prices as per the need of the clients.

Sheet Metal Components are made by piercing and blanking.

Tool making is costly maintenance is difficult. Frequent grinding, polishing have to be done to maintain tool quality.

Storing tool is space consuming.

Change of design require another tool.

Alternately sheet metal components are done by chemical milling process.

The design is transferred into Photo film form and stored. Sheet metals are then photographically coated and the required pattern is masked and the other portions which are bare metal areetched away leaving behind the required pattern. By this method you can get a burr free part.