-

Mission statement

To provide the best quality in products and services to ensure full customer satisfaction.

We achieve this with an effective and efficient quality control system which is continuously reviewed and improved.

Material and surface finishing

We produce with a wide variety of material and surface finishing.

Ferrous Metals: Different stock sizes of CRS, pre-coated or post-plated, wet spray paint or powder coating. Stainless Steels SUS 301/302/304/420/430/631, with or w/o passivation.

Aluminum, grade 1100/5052/6061/6063/7076 sheet, bars extrusions; finished in anodized, bard anodized, chromate conversion coating.

Copper, phosphor bronze, finished in anodize, bard anodize, nickled plated, black plated etc.

Quality control systems

IQC-incoming for consign material

In-process QC

SPC, CPK analysis

Final QC

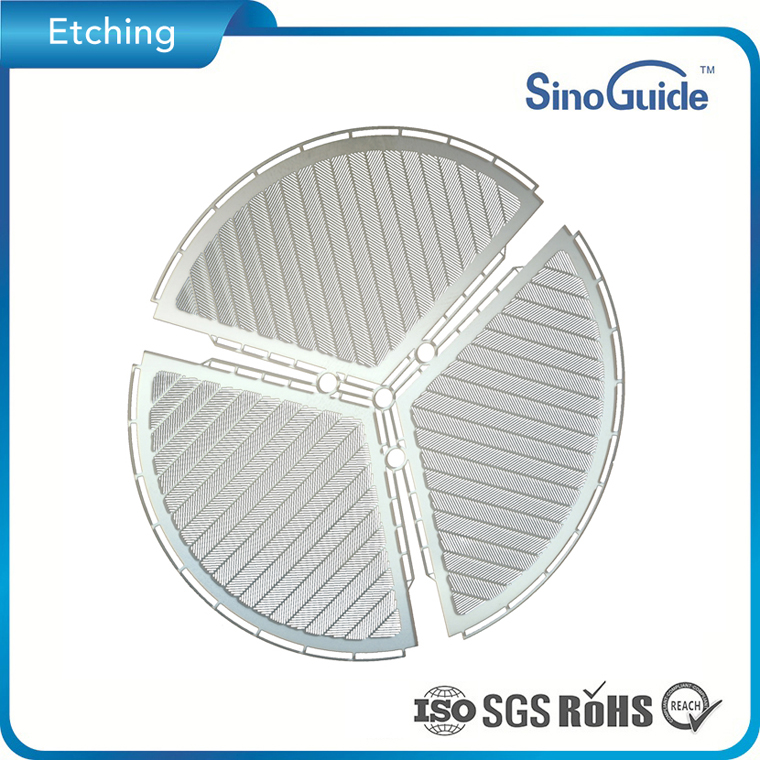

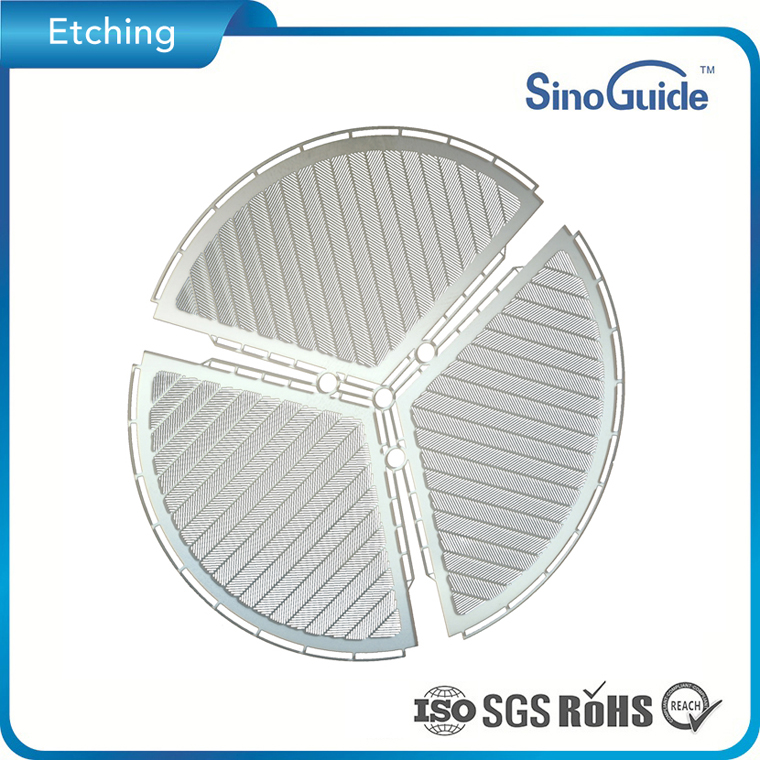

The photo chemical machining process is used in a number of applications across a wide range of industries as it can be used on just about any metal or alloy on the market, regardless of hardness. Whether your application calls for brass, copper, steel or some other form of metal you can be sure that the photo chemical machining process will get the job done.

Photo chemical machining is often used in industrial applications such as screens and meshes, masks and apertures, fuel cell components, microwave circuits, electrical contacts, encoders, semiconductors, and many other parts or products.

One of the biggest advantages of the photo chemical machining process is that it doesn’t cause unnecessary damage to the material as it only impacts the exposed areas of the metal, unlike other methods which use hard tools to get the job done. On top of that, the photo chemical machining process is able to handle applications where other methods may fail, such as semiconductor leadframes which are far too complex for other processes. We are able to work with just about any application and would love to hear about yours to see if we can provide a photo chemical solution for you.

For reliable precision components and parts, turn to SinoGuide Technology. With over 10 years in the industry you can count on us to know the right chemicals to use with your desired materials. If you have any questions about our photo chemical machining process, please contact us and we would be happy to assist you as best we can.