Products Center & Service

PROTOTYPING

We can prototype new designs at incredible speed thanks to our highly skilled design engineers, harnessing our global expertise and delivering via our local teams.

We can prototype new designs at incredible speed thanks to our highly skilled design engineers, harnessing our global expertise and delivering via our local teams.

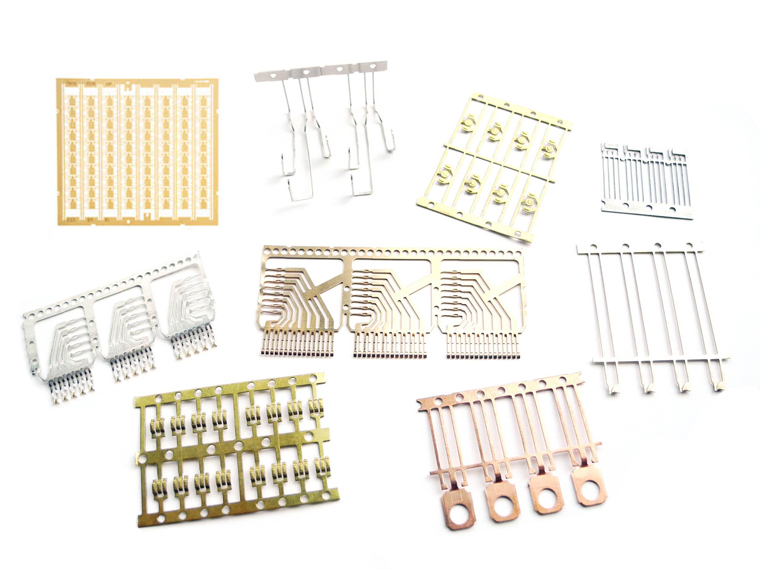

Specialist Chemical Milling & Etching of Leadframes

SinoGuide has unmatched experience in the production of bespoke lead frames, in conjunction with some of the world’s leading semiconductor packaging companies. The company’s tight tolerance manufacturing processes are ideally suited to high lead/pin count, ultra-fine pitch lead frame manufacture.

SinoGuide has pioneered downsetting, whereby the die bonding platform is indented in order to provide optimum chip protection. We have also developed a low cost masking system to reduce the cost of selective plating, making it an economical proposition, even for small volume application-specific devices.

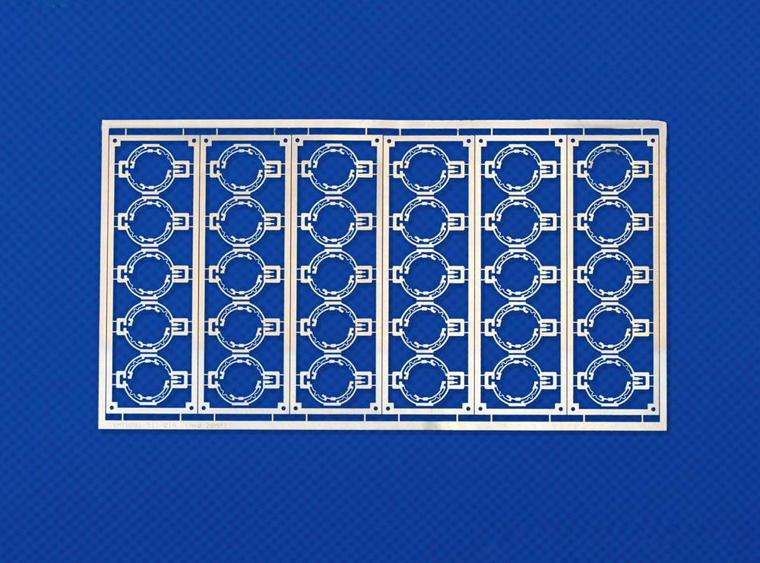

Semiconductors, leadframes and other components photo chemical machining

The photo chemical process starts with the desired shape of the product being printed onto photographic film. Once a metal material is selected it is cut down to size, coated in a photoresist and is placed between the two sheets of film and they are vacuum sealed together. From here the plate is exposed to a UV light that causes the photoresist in certain areas to harden. The extra photoresist is washed away, leaving only the areas that are to be etched behind.

The etching line is commonly a multi-chambered machine that has conveyors in order to move both the plate and the numerous spray nozzles that are a part of the machine. The etchant that does the etching is usually some form of acid depending on the material used that eats away at the exposed metal very quickly. Once the chemical has done its job it is neutralized and rinsed away, leaving behind the desired part.

The photo chemical machining process is used in a number of applications across a wide range of industries as it can be used on just about any metal or alloy on the market, regardless of hardness. Whether your application calls for brass, copper, steel or some other form of metal you can be sure that the photo chemical machining process will get the job done.

Photo chemical machining is often used in industrial applications such as screens and meshes, masks and apertures, fuel cell components, microwave circuits, electrical contacts, encoders, semiconductors, and many other parts or products.

One of the biggest advantages of the photo chemical machining process is that it doesn’t cause unnecessary damage to the material as it only impacts the exposed areas of the metal, unlike other methods which use hard tools to get the job done. On top of that, the photo chemical machining process is able to handle applications where other methods may fail, such as semiconductor leadframes which are far too complex for other processes. We are able to work with just about any application and would love to hear about yours to see if we can provide a photo chemical solution for you.

Dimensions can be held to extremely tight tolerances, with no burrs or other surface irregularities.High-density lead frames with acute profiles and ultrafine pitches allow for high pin counts. Single or double-sided lead frames are etched without incurring the stresses associated with typical machining methods. In general the turnaround time for a photo chemical machining process is quick in comparison, depending on the material used as a thicker metal will take longer to etch than a thinner metal. Here at SinoGuide Engineering you can count on our years of experience to deliver you a high quality product with a quick turnaround.

With over 10 years in the industry you can count on us to know the right chemicals to use with your desired materials. If you have any questions about our photo chemical machining process, please contact us and we would be happy to assist you as best we can. Utilizing our vast experience in etched metals, suitable for a high density of leads, SinoGuide offers metal lead frames for manufacturing of hermetic microelectronic packages.

Tel.:+86-755-89375091 Fax.:+86-755-89375092 E-mail: sales@sg-etch.com

Address: 301, Building A, North Plant, No. 103,Pingxin North Road, Mugu Community,Pinghu Street, Longgang District, Shenzhen,China 518111

copyright@2007-2015@SinoGuide Technology Ltd.