Products Center & Service

PROTOTYPING

We can prototype new designs at incredible speed thanks to our highly skilled design engineers, harnessing our global expertise and delivering via our local teams.

We can prototype new designs at incredible speed thanks to our highly skilled design engineers, harnessing our global expertise and delivering via our local teams.

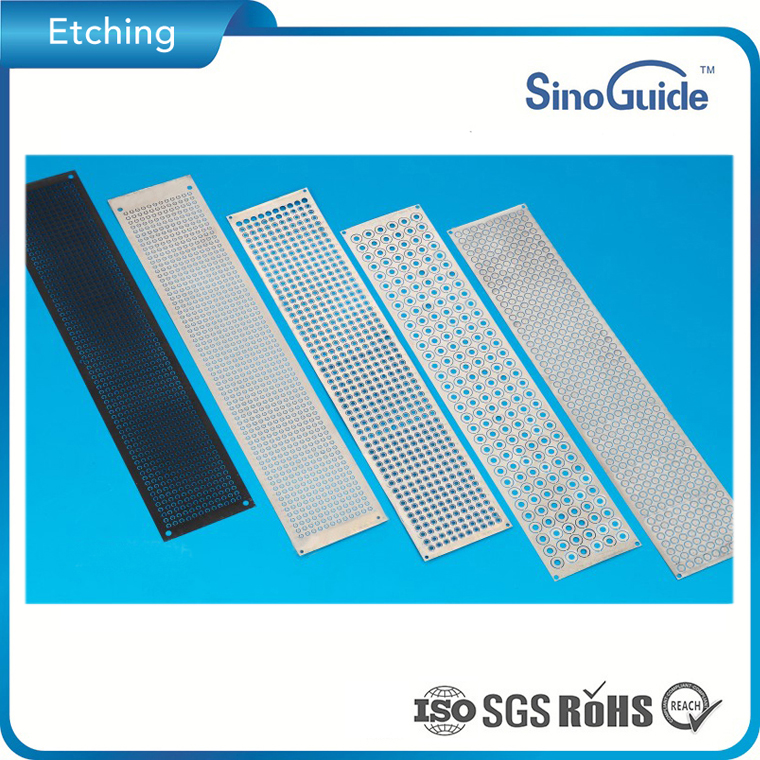

SG-etch has a wide experience in the manufacture of metal filters, meshes, screens and grids. Key requirements include high accuracy, fine apertures, no “breaks” in the bars and no burrs. Due to the bespoke nature of each user’s requirement Photofabrication offer solutions customized to your individual requirements.

Filters, meshes, grids and screens are typically used in a variety of environments. One may be trying to restrict large matter from passing through a pipe or separating specific substances during an experiment. The key requirements remain, and are all available from Photofabrication. The chemical etching process offers high precision parts, which have a burr free finish combined with low cost tooling.

For bespoke metal filters, meshes, grids and screens the manufacturing technique of choice is Chemical Milling, let us illustrate this in more detail:

Low cost tooling

High accuracy

Customised parts – you design it – we make it!

Various apertures, shapes and bar combinations

Over 10 years experience in stainless steel chemical etching metal filters, meshes, grids and screens

Burr free & Stress free manufacturing method

Prototypes – fast turnaround to meet your needs

High volume capabilities

Tel.:+86-755-89375091 Fax.:+86-755-89375092 E-mail: sales@sg-etch.com

Address: 301, Building A, North Plant, No. 103,Pingxin North Road, Mugu Community,Pinghu Street, Longgang District, Shenzhen,China 518111

copyright@2007-2015@SinoGuide Technology Ltd.